Our Focus on Decarbonization

As a global leader and innovator in our industry, we remain committed to developing low-carbon circular aluminum packaging solutions. Our growth potential relies on our ability to transform ourselves into a fully circular and decarbonized business, an ambition that is reflected in our near- and long-term Science-Based Targets.

2024 Emissions Profile

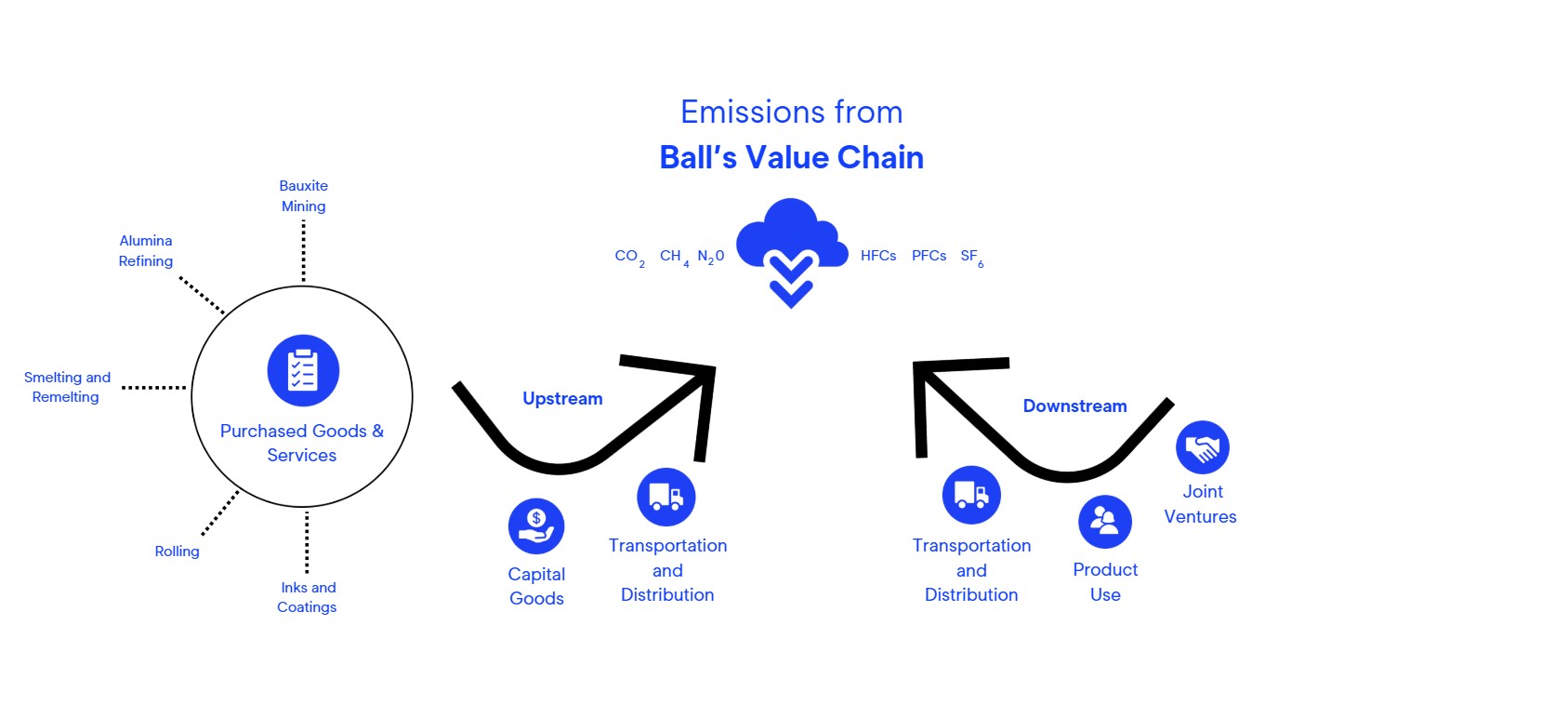

Ball’s carbon footprint is composed of the greenhouse gases (GHG) emissions emitted from our direct operations (Scope 1 & 2) and from our value chain (Scope 3). In 2024, Ball’s total carbon footprint (Scope 1, 2 & 3) was 8.1 million metric tons of carbon dioxide equivalents.

- Our Scope 1 emissions are primarily driven by our use of natural gas to dry cans after washing, cure inks and coatings in our ovens, heat water for our washing processes, burn volatile organic compounds in thermal oxidizers and – depending on the location and temperatures – comfort heating.

- Our Scope 2 emissions are tied to the electricity we use in our manufacturing processes, for example for air compressors, vacuum pumps, motors and lighting.

- Our Scope 3 emissions represent emissions outside of our direct operations and that occur in our value chains. In line with the Greenhouse Gas Protocol’s “Corporate Value Chain Accounting and Reporting Standard”, we evaluate GHG emissions from upstream emissions – such as those from our aluminum and equipment suppliers – and downstream emissions, such as those from transporting goods to our customers.

In 2024, our Global Beverage Packaging business represented 93% of Ball’s Scope 1, 2 & 3 emissions.

Progress Highlights Against Our 2017 Baseline

We are encouraged by the results we have delivered so far: by year-end 2024, our absolute GHG emissions were reduced by 21%. Ball is on track to achieve the goal of a 55% emissions reduction across Scopes 1, 2 & 3 by 2030. The chart outlines our progress on different fronts.

Ball's Climate Transition Plan

In 2023, Ball’s first Climate Transition Plan outlined our decarbonization pathway with the ambition to achieve net zero emissions between 2040 and 2050 while effectively supporting our customers’ sustainability and growth targets. We also emphasized that collaboration up and down our value chain is essential to creating a fully circular aluminum beverage packaging system.

Our targets, levers, pathways, and timelines remain unchanged and we stand by the guiding principles that we embraced back then:

- Focus on delivering significant near- and medium-term emissions reduction

- Continue advancing on levers with the best economics: circularity, efficiency and electrification

- Rely on existing technologies or innovations with high technology readiness levels

- Prioritize product stewardship to create value up and down the supply chain

Climate Transition Plan At A Glance

Our Key Decarbonization Levers, 2017-2040

The chart below shows key decarbonization levers between 2017 and 2040.

Value Chain Target Updates

When we first submitted our Science-Based Targets for approval our value chain target was aligned to a 2°C scenario, resulting in a commitment to cut GHG emissions 16% across our value chain by 2030. We came to understand that our value chain goal had become out of date, both in terms of what the latest climate science suggests and what our customers expect from Ball. Between 2020 and 2023, almost all our key aluminum Beverage and Personal & Home Care customers published net zero plans, often setting out to achieve net zero emissions by 2040. To further demonstrate how aluminum packaging can help achieve our customers’ carbon reduction objectives, we decided to update and expand our 2030 climate goals. We increased the level of ambition of our value chain Science-Based Target from a 16% to a 55% reduction in absolute GHG emissions by 2030.

Over 92% of the GHG emissions associated with our products come from within our value chain rather than our own operations. Ball’s Climate Transition Plan and vision on decarbonization are based on developing a competitive, resilient, domestic and circular value chain. We collaborate with our value chain partners to make a difference in this area, both ‘upstream’ in the products and services we purchase from suppliers, and ‘downstream’ in the way our products are collected, sorted and recycled. We are able, for instance, to work with various stakeholders to cut GHG emissions by lightweighting our products and reducing the amount of material needed, increasing recycling rates and recycled content (see Real Circularity), and utilizing low-carbon primary aluminum.

Emissions Reductions in Our Value Chain

Circularity is our key decarbonization lever to reach our 55% reduction target in our absolute Scope 3 GHG emissions. Consequently, in 2021, we articulated our vision to achieve a global recycling rate of 90% for beverage cans, bottles and cups, and an average 85% recycled content in those products.

While our goal is to increase recycled content as much as possible, some of primary aluminum will always be needed. The decarbonization of primary aluminum continues to progress, and we are following the development of various decarbonization technologies. Aluminum sector decarbonization can be achieved via a combination of proven, mature technologies and some breakthrough technologies with already high readiness levels.

With Scope 3 emissions representing over 92% of Ball’s total emissions, focusing on the decarbonization of the aluminum we procure is central to meeting our emissions reduction goal. To achieve this, value chain alignment and collaboration are key, and we work with our suppliers to secure as much lower carbon aluminum as possible. In order to send bold demand signals for low carbon aluminum and trigger needed investment to deploy the required technologies at pace and scale, in 2022 Ball joined the First Movers Coalition and pledged to buy 10% of our direct primary aluminum needs as low-carbon aluminum (less than 3 t CO2e/t of aluminum) by 2030.

Emissions Reductions in Our Own Operations

In order to meet our Science-Based Target, Ball has set two critical goals to reduce our absolute emissions by 55% by 2030:

- Achieve 100% renewable electricity globally by 2030, with an interim target of 75% by 2025.

- Achieve 30% energy efficiency improvement (electricity and natural gas) in can manufacturing (2020-2030).

Click the sections below to learn more about how we are executing our energy efficiency and renewable electricity initiatives.

In 2024, Ball achieved global renewable electricity coverage of 73%, a 13 percentage points increase versus the previous year. We achieved the most significant increase in Brazil where we achieved 100% for all our operations. This follows the achievement of 100% renewable electricity for all our U.S. manufacturing operations in 2023. Despite multiple challenges in the renewable energy market in certain locations, we continue to explore renewable solutions to reach our 2025 goal of 75% coverage globally. One major focus of ours continues to be virtual Power Purchase Agreements (PPA) in Europe to reach 100% coverage in the region prior to 2030.

To meet the electricity demand of our growing businesses as well as efforts to electrify thermal energy needs and eliminate the use of natural gas, we continue to negotiate additional VPPAs and also diversify our renewable energy strategy. Our energy procurement team evaluates direct supply opportunities with our utility partners and evaluates the potential for on-site renewable energy production in new as well as existing facilities. Our strategy centers on fostering the development of new, additional renewable energy capacity while using the purchase of unbundled RECS/GOs to meet regional goals and the needs of our customers in the immediate term.

In order to drive resource efficiency and cost reduction, as well as limit our needs for additional renewable electricity, energy efficiency also remains a key component of our strategy.

Ball is dedicated to the ongoing pursuit of continuous improvement utilizing lean manufacturing practices, optimizing existing processes, improving line efficiencies, and deploying initiatives that decrease the energy consumption per unit of production, as considered in our 2030 energy efficiency goal. There is always room for continuous improvement with lean manufacturing, process optimization, accelerating speeds and other initiatives that decrease the energy consumption per unit of product in line with our 30% energy efficiency target (2020-2030).

To learn more about our energy efficiency approach, please visit our Resource Efficiency page.

Technology-Driven Innovations for Decarbonizing the Aluminum Can Sector

The table below offers an overview of the technologies available to decarbonize de aluminum can sector by their level of maturity.